Parker Electro-mechanical

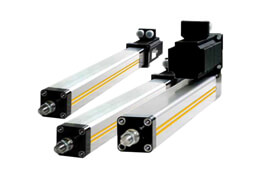

ORIGA SYSTEM PLUS is a completely modular concept, enabling electric drives to be combined with guides and control modules for all kinds of applications.

The main system carriers are the drives themselves, consisting of extruded aluminium profiles with double dovetail slots on three sides, providing direct mounting for all modular options.

Modular System

* Electric Toothed Belt Drive

* For applications with higher speeds and precise movement and positioning for longer travel.

* Electric Screw Drive

* For higher drive power and precise movement and positioning.

18 additional guide variants provide any required precision, performance and load capacity.

Compact solutions, easy to install and simple to retrofit.

Valves and control elements can be mounted directly on the pneumatic drive.

A wide range of mounting options provides great installation flexibility.

Introduced as the world's first complete servo driven electric cylinder system, the ET Series combines an unparalleled design with a variety of options that make it easy to integrate into both new and existing applications. Produced to hard metric ISO standards, the ET Series can mount into existing fluidpower cylinder applications, adding infinite programmability to the durability and long life expected of hydraulic and pneumatic cylinders. Combined with a Parker Hannifin motor and control system, the ET Series arrives at the customer's dock complete and ready to mount. The ET Series can be ordered with a pre-mounted Parker Hannifin step motor.

* Extra-long length rod bearing

* Precision anti-rotation roller bearing rod support carriage

* Ground and polished stainless steel thrust tube

* Angular contact thrust bearings.

* Anodized aluminum cylinder body with integral slots for limit sensors

* Five profile sizes (32, 50, 80, 100, 125 mm)

* Precision rolled ball screws or Acme lead screws

* Inline or parallel motor mounting

* Nine different ISO mounting options (including flange mounts, trunnion mount and clevis mount)

* Six different rod end options including Linear Rod Guide Module for additional side load support.

Ready to mount to servo motors and reduction systems

* Using Parker Electric Cylinders, Rodless Actuators and Structural Aluminum Framework

Many applications require multi-axis integration rather than a single axis solution. With their modular design, both ET Series Electric Cylinders and ER, ERV and LCB Series Rodless Actuators are well suited to multi-axis connection. The Actuator Division is ready to provide a multi-axis solution to your application by providing the connection hardware in addition to standard and modified actuator products to make integration of the system into the application simple and reliable.

* Transition kits for connecting ER Series Rodless Actuators

* Transition kits to connect ET Series Linear Actuators to ER Series Rodless Actuators

* Non-driven Idler Units to provide additional bearing support

* Outrigger bearing units to control deflection and provide additional loading capacity

* Link-shafts to connect belt-driven actuators to a single motor/gearbox

The Daedal Division is a leading producer of linear and rotary positioning devices including ball bearing and cross roller bearing slides, manually actuated stages and a complete line of motorized tables. The Daedal product line provides a wide range of capabilities. Standard catalog items individually offer: travel to 240 inches, translation speeds of 200 inches per second, linear positioning accuracy of 0.000080 inches/inch and load capacities of 2300 lbs. Complete multi-axis customized systems are quoted upon request.

* Actuators - linear

* Bearings - ball slides

* Bearings - cross roller slides

* Bearings - rotary

* Micro positioners - micro positioners

* Micrometers - micrometers

* Positioning systems - custom design

* Positioning systems - multi axis

* Positioning systems - servo motor

* Positioning systems - stepping motor

* Positioning tables - ball bearing

* Positioning tables - cross roller

* Positioning tables - custom designed

* Positioning tables - linear motor driven

* Positioning tables - long travel rail

* Positioning tables - precision rotary

* Positioning tables - square rail

* Robots, gantry - electromechanical

* Stages - digital micrometer

* Stages - micrometer

* Stages - multi-axis precision

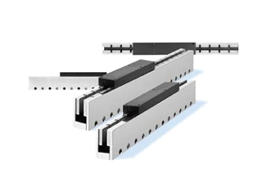

The MaxPlus linear servo motors are revolutionizing the industry with its superior linear motion technology. Available in both dual row and single row magnet configurations, MaxPlus linear motors are designed to exceed the rigorous demands required in advanced manufacturing, assembly, test and inspection environments.

Our MaxPlus line of linear servo motors utilizes an ironless core design that provides high peak-to-continuous force ratios and extremely high acceleration in high-speed applications. MaxPlus linear motors have superior thermal properties and the highest force to coil weight available. All of which means you can expect exceptional performance, smooth motion, high accuracy, plus unparalleled acceleration and stiffness. Compumotor is continually working with new and emerging technologies to improve our product offering. For example, MaxPlus linear servo motors utilize a patented, automated machine winding technology that results in excellent unit-to unit consistency at a significantly lower cost.

* Continuous force up to 325 lbs./1446N

* Peak force up to 1620 lbs./7206N

* High force to coil mass ratio

* High accuracy/repeatability

* Efficient thermal performance

* Velocities > 10M/sec. Accelerations > 10G

* Zero magnetic preload

* Sinusoidal or hall effect commutation

* Thermistor

* Thermostat optional

* High-performance rare earth magnets

* Low inductance coil for fast response

* Non-contacting assemblies

* Continuous track to 72 in./1.8m*

* Configurable connections/cable options

* Fully customizable design

2000 Series available to 72 in./1.8m

The 404XE positioners combine versatility with rugged construction in a compact motion platform that is ideal for 24/7 process automation. A high efficiency ballscrew drive, recirculating square rail bearings and high strength aluminum body are the result of innovative engineering that has reduced costs while improving performance. Travels to 700 mm.

* 100 % Duty Cycle

* Repeatability to ±20 µm

* High Strength Design

* Easy Multi-Axis Mounting

* Locating Dowel Holes

* Linear feedback

* Sensor packs

* Parallel motor mounting

* Clean room preparation

* ±1.3 µm bidirectional repeatability

* Maximum load: Normal - 14 400 N; axial - 4510 N.

* Travels up to two meters

* High efficiency ballscrew drive

* High strength extruded aluminum body

* Precision ground mounting surface

* IP30 rated strip seals

* 100% certified with laser interferometer tests

* Optional cleanroom prep to class 10

Backlash (arc minutes) |

Config. |

Cont Torque Tc (Nm) |

Feedback |

Frame Size |

Gear Teeth |

IP Rating |

Noise (db) |

Ratios |

Windings (Vdc) |

|

Gearmotor (GM) |

< 10 |

In-Line |

3 to 60 |

Encoder |

60 to 115 mm |

Helical |

IP 65 |

<68 |

5, 7, 10 |

160 Vdc |

Servo Wheel Series |

|

brushless dc motor with planetary gears |

|

Encoder |

6 Inch Wheel Diameter |

Straight Tooth Planetary |

IP54 |

|

|

|

Gen II Stealth Gearhead "In-Line" PS |

< 3 |

In-Line |

5 to 1,808 |

|

60 to 220 mm |

Helical Planetary |

IP 65 |

<68 |

3 to 100 |

|

Gen II Stealth Gearhead "In-Line" PX |

< 8 |

In-Line |

18 to 158 |

|

60 to 115 mm |

Helical Planetary |

IP 65 |

<70 |

3 to 100 |

|

Gen II Stealth Gearhead "Right Angle" RS |

< 4 |

Right Angle |

11 to 1,808 |

|

60 to 220 mm |

Helical Planetary / Spiral Bevel |

IP 65 |

<72 |

5 to 100 |

|

Gen II Stealth Gearhead "Right Angle" RX |

< 14 |

Right Angle |

7 to 45 |

|

60 to 115 mm |

Helical Planetary |

IP 65 |

<70 |

5 to 100 |

|

Stealth Gearhead "Right Angle" MultiDrive |

< 4 |

RT - Right Angle Thru Bore, RD - Right Angle Double Shaft, RB - Right Angle |

34 to 565 |

|

90 to 220 mm |

RT - Spiral Bevel / Helical, RD and RB - Spiral Bevel |

IP 65 |

|

RT - 3 to 30 (5 ratios), RD - 1 to 30 (7 ratios), RB - 1 to 3 (3 ratios) |

|

Spur Gearhead "Inline (NE) and Right Angle (NR)" NEMA |

NE - < 10 |

NE - In-Line |

50 to 350 |

|

NE - NEMA 23 to 42(3 sizes) |

NE - Spur |

IP54 |

|

NE - 3 to 100(9 ratios) |

|

PV Series "In-Line Power and Versatility" |

< 18 |

IN-LINE |

3.5 to 70 |

|

40,60,90,115 mm NEMA17,23,34,42 |

Straight Tooth Planetary |

IP64 |

<65 |

3, 4, 5, 7, 10, 12, 15, 16, 20, 25, 30, 35, 40, 50, 70, 100 |

|

Parker XRS Series "standard" Cartesian robot modules are the ideal solution for cost effective automation in life sciences, semiconductor, electronics, automated assembly, dispensing, and many other applications.

Standard XRS Systems are pre-engineered to optimize work-space, simplify selection, shorten delivery and lower costs.

Scalability

With 3 size platforms and 124 standard systems you can find a standard solution for your application.

Technology

A unique mix of linear servo motor and ballscrew drive technology provides optimized dynamic performance for today's demanding automation applications. Reliability

XRS Systems are built from Parker's XR/LXR linear positioners, time tested and proven in thousands of applications worldwide